- FE News»

- PPS News»

- Nov. 18, 2025

- Holiday Closing Notice [2025-2026]

- Jun. 23, 2025

- Notice of Specification Change for ECHELON Zen-Xero Series Maintenance Bags

- Oct. 31, 2024

- [News Release R-1020] Release of "ECHELON Zen-Xero DYNAMIX”

- May. 15, 2024

- [News Release R-1019] Release of "ECHELON Ver.3.0”

- Oct. 02, 2023

- [News Release R-1018]Compound that achieves a genuine finish Full Renewal of “KATANA” Series

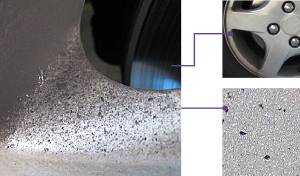

Aluminum Wheels and Dirt

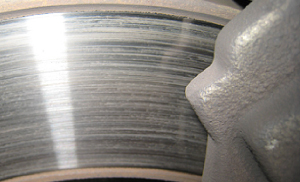

When it comes to dirt adhering to wheels, the first thing we think of is a wheel completely blackened by carbon soot, as seen in the picture. The main cause of this dirt is the brake pads rubbing against the rotors during braking and burning to ash. On top of that, sand and mud, as well as oil-based grime such as pitch and tar, are kicked up from the road, adhering to and accumulating on the surface. Another source of dirt is the iron dust which is abraded from the brake rotors. Most people think that iron dust comes from the brake pads, but they produce mainly ash when they combust due to rubbing with the brake rotors. So called “iron dust” mostly comes from material which is abraded from the brake rotors by the pads. In recent years there has been a trend toward using non-metallic brake pads made from resin or fiber. Products which aim to reduce brake pad dust are available on the market. The reason that the wheels on non-Japanese vehicles and sports cars get blackened so easily is that their pads focus on braking strength and so are consumed quickly.

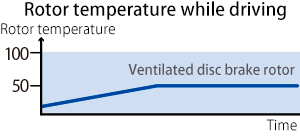

The temperature of the rotors and pads while driving on city streets varies by car but generally sits between 50–100℃. On highways, the temperature climbs to 100–150℃. During breaking the temperature spikes even higher. Under such high temperatures, the abraded iron dust is dispersed and adheres to the wheel’s surface as though it has pierced through, making it a very difficult type of contaminant to remove. Pitch and tar are oil-based contaminants which are melted from the asphalt. Because they are sticky, wiping at them carelessly will result in the grime spreading even further.