- FE News»

- PPS News»

- Nov. 18, 2025

- Holiday Closing Notice [2025-2026]

- Jun. 23, 2025

- Notice of Specification Change for ECHELON Zen-Xero Series Maintenance Bags

- Oct. 31, 2024

- [News Release R-1020] Release of "ECHELON Zen-Xero DYNAMIX”

- May. 15, 2024

- [News Release R-1019] Release of "ECHELON Ver.3.0”

- Oct. 02, 2023

- [News Release R-1018]Compound that achieves a genuine finish Full Renewal of “KATANA” Series

Aluminum Wheels and Cleaning

When cleaning a wheel, it is important whether a clear coat finish was applied to it.

Normal coatings usually have a clear coat, but chrome plating and alumite simply have the metal as the top layer. These surfaces can be easily damaged by chemicals and require care when cleaning. Furthermore, if a coating has scratches or cracks in it, the chemicals can seep through and contact the aluminum base. This may lead to the damage spreading, so care must be taken.

■Chemical Cleaners

Compatibility of Materials and Chemicals

Whether or not a coating has been applied, wheel cleaning is essential to aesthetics when coating or washing a car. As discussed previously, when cleaning wheels the type of finish and contaminant will inform how they should be cleaned. It is important to use the appropriate process for the situation. First, let us look at a table which shows the general compatibility between different finishes and chemicals.

| Product | Metallic Coating | Hyper Coating | Sputter Coating | Machined | Chrome Plating | Alumite |

|---|---|---|---|---|---|---|

| Neutral Body Shampoo | ○ | ○ | ○ | ○ | ○ | ○ |

| Alkaline Cleaner | ○ | ○ | ○ | △ | △ | △ |

| Iron Dust Remover | ○ | ○ | ○ | ○ | △ | △ |

| Acidic Cleaner | ○ | ○ | × | △ | × | × |

○・・・Can be used generally

△・・・Cannot be used if degraded

×・・・Cannot be used due to damage

*The table is only a rough guide according to type.

When actually using a product, please check its compatibility as it is applied.

△・・・Cannot be used if degraded

×・・・Cannot be used due to damage

*The table is only a rough guide according to type.

When actually using a product, please check its compatibility as it is applied.

Use and Application of Compatible Chemicals for a Product

Aluminum Cleaners / Blacklean

Stubborn residues which cannot be completely removed with alkaline cleaners or iron dust removers can be dissolved and removed with the power of acid.

This product has some risks, so please check that it is not damaging the wheel as you use it. You must never use this product on metal surfaces such as plating or alumite.

This product has some risks, so please check that it is not damaging the wheel as you use it. You must never use this product on metal surfaces such as plating or alumite.

FRESH CLEAR AUTHORIZED/LIMO CHEMIE

Removes oil-based dirt, such as pitch and tar, and brake dust grit.

A must-have item for wheel cleaning. Breaks down and removes stubborn oil-based dirt which shampoos can’t break down. It is strongly alkaline and aggressive toward metal surfaces such as chrome plating and alumite. Please use with care.

A must-have item for wheel cleaning. Breaks down and removes stubborn oil-based dirt which shampoos can’t break down. It is strongly alkaline and aggressive toward metal surfaces such as chrome plating and alumite. Please use with care.

Iron Cut Series

Iron Dust from Brake Rotors

This neutral type can be used with coating or chrome plating. However, please be careful when using it with deteriorated wheel surfaces with cracks or scratches. Chemically dissolves areas of oxidized iron dust, causing the dust to float from the surface it is attached to and be removed.

This neutral type can be used with coating or chrome plating. However, please be careful when using it with deteriorated wheel surfaces with cracks or scratches. Chemically dissolves areas of oxidized iron dust, causing the dust to float from the surface it is attached to and be removed.

■Polishing

Another way of cleaning: “Polishing”

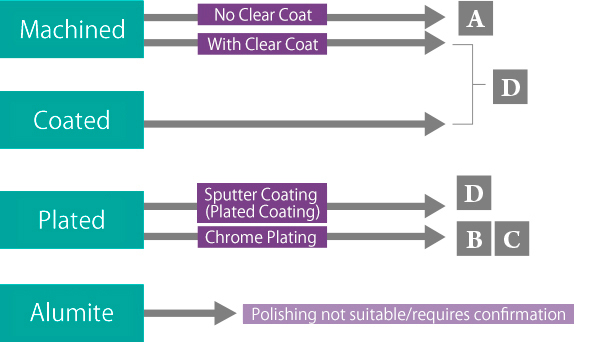

There are many types of finish for aluminum wheels, and each different surfacing process requires a different method of care. Below we explain different methods based on the characteristics of each type of wheel finish.

FE Compatible Products

A 3M MAG&ALUMINUM POLISH 39529

This specialized polishing compound is perfect for polishing pure aluminum and magnesium wheels with no clear coating, such as billet wheels used on custom cars. It removes oxidation, rain spots, grime, and brake dust which have adhered to the material, restoring it to its original luster.

B METAL AID Chrome One Step Finish

This specialized polishing compound is optimal for polishing chrome plated surfaces. It removes oxidation and substances which cause clouding without damaging the hard, weather-resistant chrome layer, restoring it to its original shine. Because it is a strong abrasive, using it on sputter plated surfaces will cause scratches and clouding. Please use carefully.

C 3M CHROME&METAL POLISH 39527

This specialized polishing compound is suitable for polishing chrome plating. It removes oxidation, corrosion, and clouding from the surface, reviving the original luster.

D Various Compounds

There are many products which can be used as polishing compounds for painted surfaces, such as the PM Series and the Menzerna PX Series.Just as with polishing painted surfaces, using rough compounds with high abrasiveness will cause scratches and polishing marks, so please use with care.

How to Polish Aluminum Wheels

Machined

■Optimal Method

Machined wheels generally have a clear coat applied to the machine finished aluminum surface. In such cases, use the same method as with coated finishes. However, for pure aluminum use a special aluminum polishing compound. Uncoated aluminum and magnesium are delicate, so be careful when polishing them.

Machined wheels generally have a clear coat applied to the machine finished aluminum surface. In such cases, use the same method as with coated finishes. However, for pure aluminum use a special aluminum polishing compound. Uncoated aluminum and magnesium are delicate, so be careful when polishing them.

Compatible Product Examples

No Clear Coat

3M MAG&ALUMINUM POLISH 39529

With Clear Coat

Various Compounds

(SUPER PM Series Menzerna PX Series)

No Clear Coat

3M MAG&ALUMINUM POLISH 39529

With Clear Coat

Various Compounds

(SUPER PM Series Menzerna PX Series)

Billet wheels which have been cut out of pure aluminum are expensive but quite popular on the custom car market. Because they have no clear coat, they are very delicate and require frequent maintenance. Polishing them with a special aluminum polishing compound will remove cloudiness and restore their shine.

Coated

■Optimal Method

This type of finish has the highest compatibility with various cleaning chemicals, and as a result it rarely has dirt left over after cleaning. Rather than to remove dirt, polishing is a means of addressing physical damage on the surface. For example, an area which has been dulled by a hard sponge or a cloudy area which cannot be removed with cleaning can generally be polished using a compound just as with the body. For large application areas, polishing can be done with a machine rather than by hand polishing.

This type of finish has the highest compatibility with various cleaning chemicals, and as a result it rarely has dirt left over after cleaning. Rather than to remove dirt, polishing is a means of addressing physical damage on the surface. For example, an area which has been dulled by a hard sponge or a cloudy area which cannot be removed with cleaning can generally be polished using a compound just as with the body. For large application areas, polishing can be done with a machine rather than by hand polishing.

Plated

■Optimal Method

Although the chrome plating itself is harder and more robust than normal coatings, they generally cannot be cleaned using alkaline or acidic chemicals. The resulting drawback is that a small bit of dirt or a scratch or dull spot on the once mirror-like surface stands out in stark contrast.

Unlike coated finishes, chrome plating does not have a clear coat on the surface, meaning the chrome layer must be polished directly. By using a lineup of specialized polishing compounds, effects on the chrome layer can be carefully constrained and the surface can be cleaned efficiently.

Although the chrome plating itself is harder and more robust than normal coatings, they generally cannot be cleaned using alkaline or acidic chemicals. The resulting drawback is that a small bit of dirt or a scratch or dull spot on the once mirror-like surface stands out in stark contrast.

Unlike coated finishes, chrome plating does not have a clear coat on the surface, meaning the chrome layer must be polished directly. By using a lineup of specialized polishing compounds, effects on the chrome layer can be carefully constrained and the surface can be cleaned efficiently.

Compatible Product Examples

Sputter Coating

METAL AID Chrome Micro Finish

Chrome Plating

METAL AID Chrome One Step Finish

3M CHROME&METAL POLISH 39527

Sputter Coating

METAL AID Chrome Micro Finish

Chrome Plating

METAL AID Chrome One Step Finish

3M CHROME&METAL POLISH 39527

Compounds for coated wheels vs. compounds for chrome plated wheels

Compared to general polishing compounds for coated wheels, polishing compounds for chrome plating tend to contain more polishing agents such as alumina, allowing them to be used on the harder plated surface. Additionally, these compounds often include ammonium hydroxide, a component used when forming the plating. This formulation not only increases affinity with the surface being polished but also prevents damage to the plating, which is weak to both alkali and acid.

Compared to general polishing compounds for coated wheels, polishing compounds for chrome plating tend to contain more polishing agents such as alumina, allowing them to be used on the harder plated surface. Additionally, these compounds often include ammonium hydroxide, a component used when forming the plating. This formulation not only increases affinity with the surface being polished but also prevents damage to the plating, which is weak to both alkali and acid.

Chrome plating surface is cloudy and has no shine due to layer of oxidation, even after washing

Polishing with specialized polishing compound brings back the shine of the chrome plating

Alumite

■Optimal Method

Due to the properties of alumite surfacing, polishing will remove the alumite layer and cause it to lose its shine and quality. Sport car wheels, in particular, which have colored alumite will have their colors change. Consequently, these wheels are generally not suited to polishing. If polishing is necessary, it should first be tested in a not easily visible spot before continuing the process.

Due to the properties of alumite surfacing, polishing will remove the alumite layer and cause it to lose its shine and quality. Sport car wheels, in particular, which have colored alumite will have their colors change. Consequently, these wheels are generally not suited to polishing. If polishing is necessary, it should first be tested in a not easily visible spot before continuing the process.

Example of polishing alumite

The matte alumite spoke has been polished, making it shine, reflect light, and generally differ from the rest of the wheel in appearance. When polishing alumite, you must first test it in a not easily visible spot.