- FE News»

- PPS News»

- Jun. 23, 2025

- Notice of Specification Change for ECHELON Zen-Xero Series Maintenance Bags

- Oct. 31, 2024

- [News Release R-1020] Release of "ECHELON Zen-Xero DYNAMIX”

- May. 15, 2024

- [News Release R-1019] Release of "ECHELON Ver.3.0”

- Oct. 02, 2023

- [News Release R-1018]Compound that achieves a genuine finish Full Renewal of “KATANA” Series

- Jun. 27, 2023

- [News Release] A final finishing compound that achieves a beautiful wet gloss. "KATANA DARK-SHOT" is Released.

Polisher operation modes and different functionalities

Polishers are the main players in polishing work, and there are various types of polisher with different modes of operation. Although this is common knowledge among detailers who use these tools everyday, as a wider variety of products and more polisher types have become available in recent years, we thought to summarize the different mechanisms and functionalities now available. Please use this as a reference for selecting polishers and using them in the detailing process.

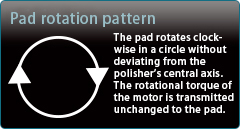

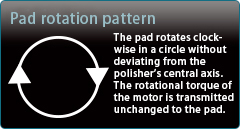

Rotary action

Polishing power:☆☆☆

Speed:☆☆☆

Finishing:☆☆

Control:☆

■ Main applications for compound use

The cornerstone of polishing

This is the most commonly used type of polisher in detailing, handling everything from scratch removal to finishing. These polishers have excellent polishing power and polishing speed. However, because they tend to leave swirling marks and holograms when finishing dark-colored vehicles, other types are more suitable for that work.

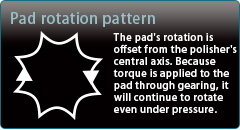

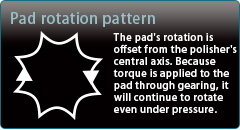

Gear action

Polishing power:☆☆

Speed:☆☆

Finishing:☆☆☆

Control:☆☆

■ Main applications for compound use

Balance between polishing performance and finishing

The action of this type is intermediate between rotary and dual action polishers. It provides moderate polishing power while being more suitable for delicate finishing of dark-colored vehicles than rotary polishers. Its moderate torque and irregular rotation help reduce the occurrence of swirling marks and holograms.

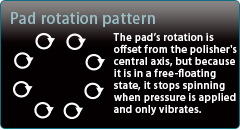

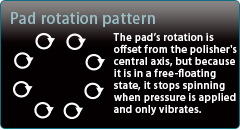

Dual action

Polishing power:☆-☆☆

Speed:☆

Finishing:☆☆☆

Control:☆☆☆

■ Main applications for compound use

Achieving a delicate finish

This type has little mechanical torque, making it easy to control, but its polishing power and speed is inferior to the other two types. These polishers are mainly used for removing holograms, simple elimination of water stains and application of wax or coatings. In recent years, however, types intended for polishing have been developed, allowing for efficient finishing.

Polisher operation modes and different functionalities

Polishers are the main players in polishing work, and there are various types of polisher with different modes of operation. Although this is common knowledge among detailers who use these tools everyday, as a wider variety of products and more polisher types have become available in recent years, we thought to summarize the different mechanisms and functionalities now available. Please use this as a reference for selecting polishers and using them in the detailing process.

Rotary action

Polishing power:☆☆☆

Speed:☆☆☆

Finishing:☆☆

Control:☆

■ Main applications for compound use

The cornerstone of polishing

This is the most commonly used type of polisher in detailing, handling everything from scratch removal to finishing. These polishers have excellent polishing power and polishing speed. However, because they tend to leave swirling marks and holograms when finishing dark-colored vehicles, other types are more suitable for that work.

Gear action

Polishing power:☆☆

Speed:☆☆

Finishing:☆☆☆

Control:☆☆

■ Main applications for compound use

Balance between polishing performance and finishing

The action of this type is intermediate between rotary and dual action polishers. It provides moderate polishing power while being more suitable for delicate finishing of dark-colored vehicles than rotary polishers. Its moderate torque and irregular rotation help reduce the occurrence of swirling marks and holograms.

Dual action

Polishing power:☆-☆☆

Speed:☆

Finishing:☆☆☆

Control:☆☆☆

■ Main applications for compound use

Achieving a delicate finish

This type has little mechanical torque, making it easy to control, but its polishing power and speed is inferior to the other two types. These polishers are mainly used for removing holograms, simple elimination of water stains and application of wax or coatings. In recent years, however, types intended for polishing have been developed, allowing for efficient finishing.