- FE News»

- PPS News»

- Jun. 23, 2025

- Notice of Specification Change for ECHELON Zen-Xero Series Maintenance Bags

- Oct. 31, 2024

- [News Release R-1020] Release of "ECHELON Zen-Xero DYNAMIX”

- May. 15, 2024

- [News Release R-1019] Release of "ECHELON Ver.3.0”

- Oct. 02, 2023

- [News Release R-1018]Compound that achieves a genuine finish Full Renewal of “KATANA” Series

- Jun. 27, 2023

- [News Release] A final finishing compound that achieves a beautiful wet gloss. "KATANA DARK-SHOT" is Released.

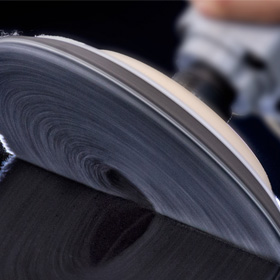

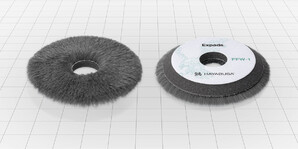

FFW (Freed Feather Wool)

Freed Feather Wool

- Micro Feather Wool Pads evolved even further !

-

Among various kinds of wool pads, long-fiber wool pads were propelled into a current mainstream of buffing pads by our Micro Feather Wool Pads. Since the time majority of polishing workers used single polishers, Micro Feather Wool Pads have been widely favored because of a good balance between excellent polishing performance and uniform finish.

Then we launched the FFW (Freed Feather Wool) with sheep wool processed by our latest technology called "AirFreed Manufacturing Method" to meet the current needs for working on more diversified painted surfaces. They are available in the three most standard sizes. They all come with frequently used fiber length of 22 mm.

- Best for use with single polishers

-

Single polishers often generate a great deal of heat during a polishing work. The effect of AirFreed Manufacturing Method helps FFW (Freed Feather Wool) to reduce the heat accumulated at a painted surface and prevent polishing compounds from sticking to the yarns so that they spread uniformly to get the best polishing performance of the compounds. The Pads allow compounds drain smoothly from between the yarns, hence avoiding excessive polishing and enabling you to achieve an effective finish. In addition, the AirFreed effect helps yarns to keep a space from each other and not be felted, which means that the wool can maintain lasting springiness without getting flattened. The Pads reduce compounds burned to the tip of yarns, making it easy to wash them and restore their natural original texture. You can use these pads with vertical polishers as well as with angled polishers.

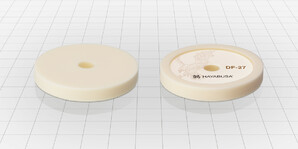

Semi-hard type

This type is more springy than ordinary foam base yet has flexibility at the same time. It achieves both polishing and finishing performance.

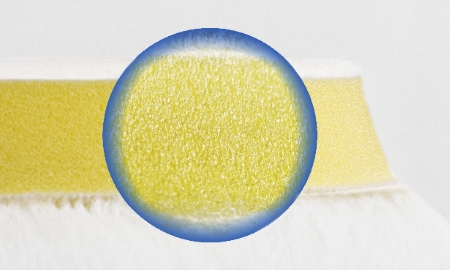

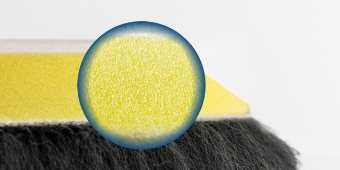

- AirFreed Manufacturing Method

-

This is a method specially designed for manufacturing this world first faux fur like polishing pads with a two-layered special treatment around each worsted yarn*.

NOTE: Worsted yarn is a yarn made by combing long wool fibers, removing short fibers and spinning them together.

- [Fiber Length : 22mm]

-

【Wool】 Material sourced from Australia

/ Product made in Japan

/ Product made in Japan

【Materials (polyurethane foam, adhesive, etc.)】 Material sourced from / Product made in Japan

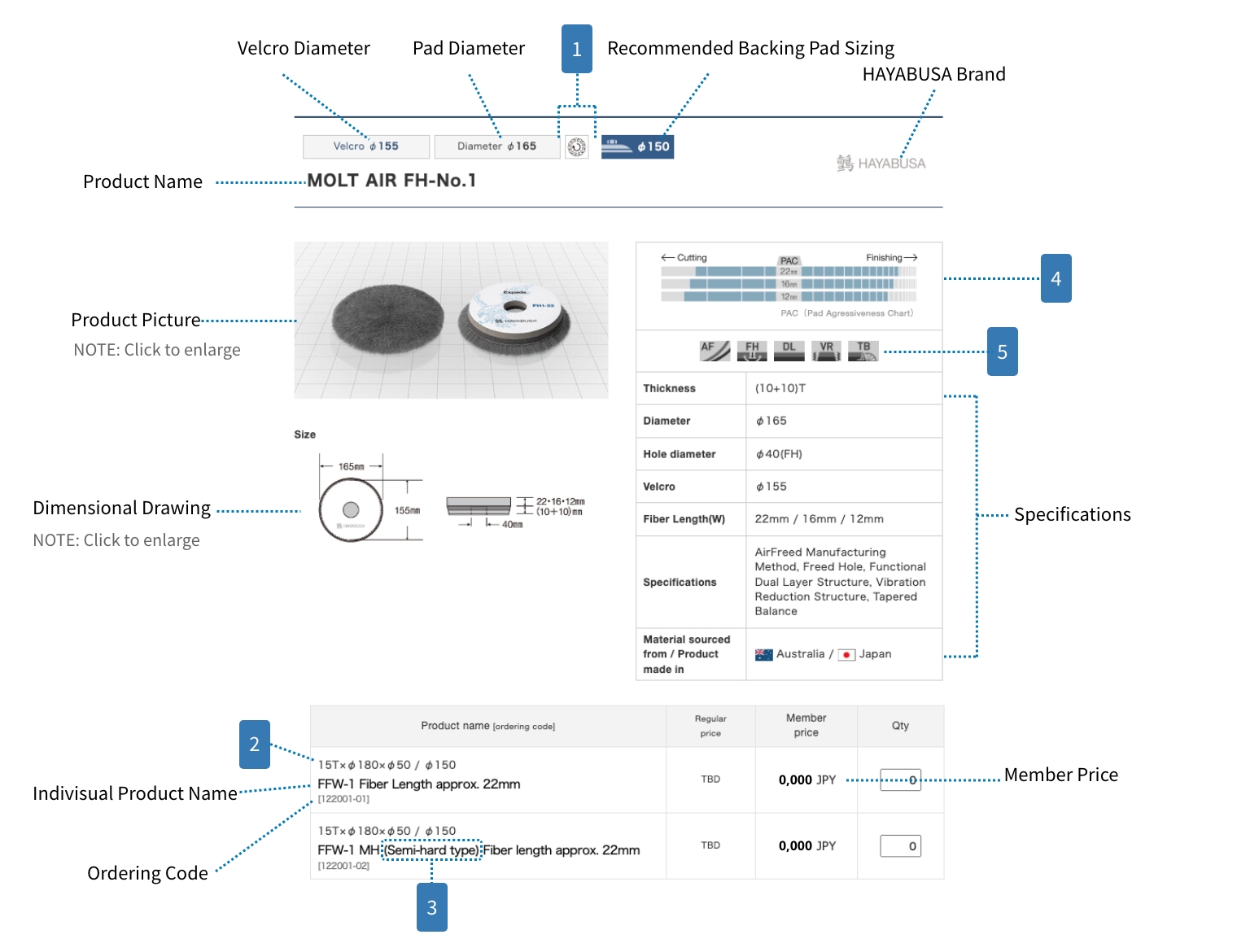

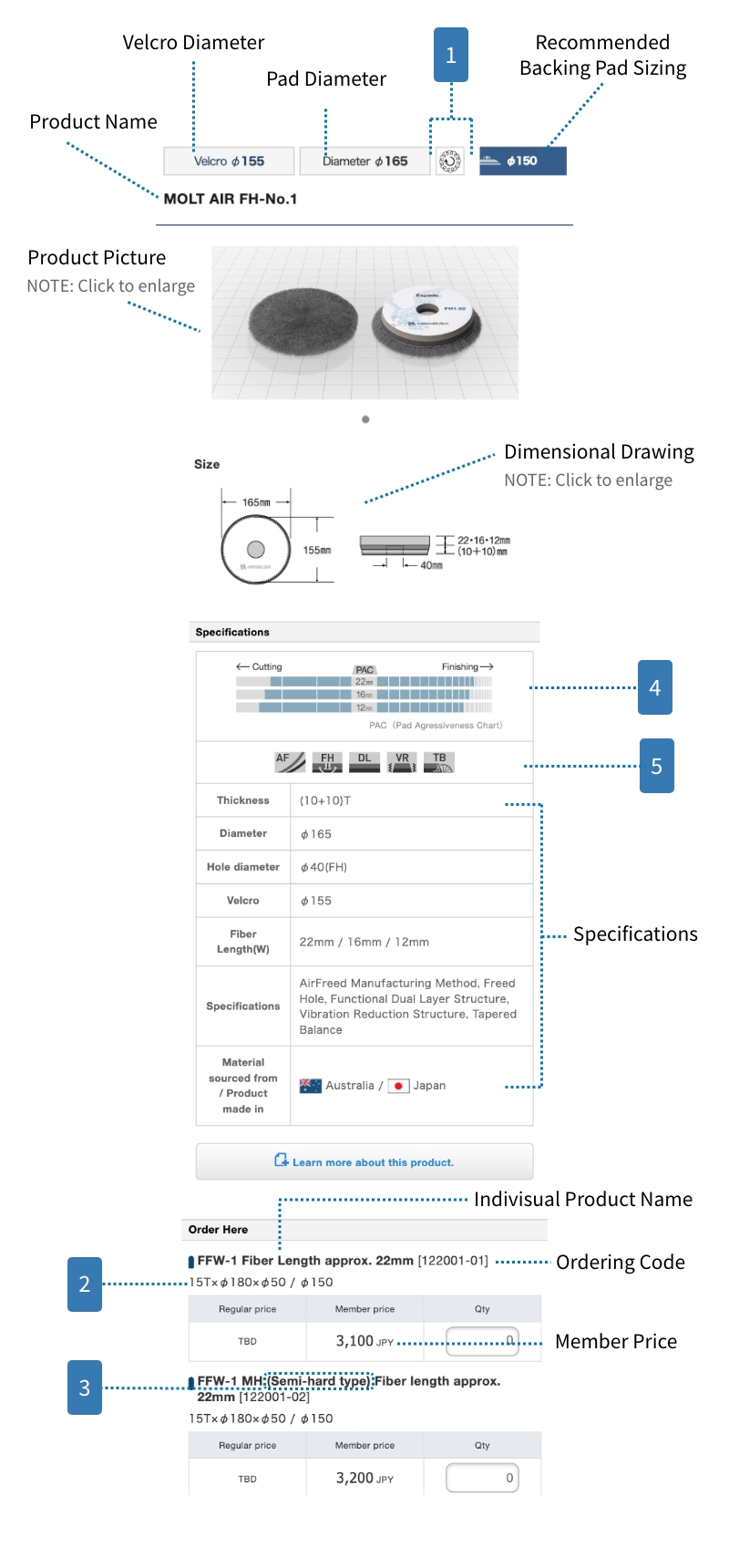

How to Read the Item page

Read more +

| Number of results:3 | 1 - 3 |

|---|

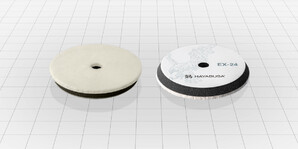

FFW No.1

- Velcro φ150

- Diameter φ180

φ150

φ150

- Thickness:15T

- Diameter:φ180

- Hole diameter:φ50

- Velcro:φ150

φ150

φ150

- Fiber Length(W):22mm

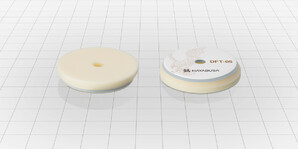

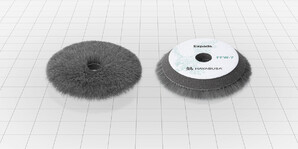

FFW No.7

- Velcro φ125

- Diameter φ150

φ125

φ125

- Thickness:15T

- Diameter:φ150

- Hole diameter:φ30

- Velcro:φ125

φ125

φ125

- Fiber Length(W):22mm

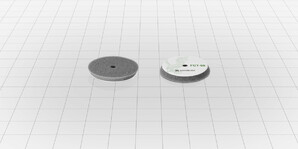

FFW No.13

- Velcro φ75

- Diameter φ80

φ75

φ75

- Thickness:10T

- Diameter:φ80

- Hole diameter:φ10

- Velcro:φ75

φ75

φ75

- Fiber Length(W):22mm

| Number of results:3 | 1 - 3 |

|---|