- FE News»

- PPS News»

- Jun. 23, 2025

- Notice of Specification Change for ECHELON Zen-Xero Series Maintenance Bags

- Oct. 31, 2024

- [News Release R-1020] Release of "ECHELON Zen-Xero DYNAMIX”

- May. 15, 2024

- [News Release R-1019] Release of "ECHELON Ver.3.0”

- Oct. 02, 2023

- [News Release R-1018]Compound that achieves a genuine finish Full Renewal of “KATANA” Series

- Jun. 27, 2023

- [News Release] A final finishing compound that achieves a beautiful wet gloss. "KATANA DARK-SHOT" is Released.

Types and causes of deterioration

As we have demonstrated, headlights deteriorate due to a variety of factors. The polycarbonate in headlights does not just suddenly start deteriorating. Rather, it begins gradually from the surface. We will now review the problems that occur from start to end.

Deterioration due to the effects of ultraviolet rays and contaminant accumulation

This is thought to be the most common cause of deterioration. In this phenomenon, petroleum-based solvents (such as wax) and vegetable oils (pine resin, pollen, etc.) accumulated on the surface deteriorate due to ultraviolet rays from the sun, forming an oxide film. When that happens, it corrodes the hard coat, eventually causing the hard coat itself to deteriorate. This occurs easily under long term exposure to ultraviolet rays. It is the reason that vehicles that have deteriorated over time sometimes only show damage on one side in cases where the vehicle has been parked in the open or a carport where the sun only hits half of the vehicle. It is also thought to be the reason that even vehicles that are not parked in the open begin to deteriorate from the top of the headlight, which tends to be exposed to ultraviolet rays during driving.

Progressive stages of deterioration

- Scratches of the hard coat due

to flying gravel, etc.

The hard coat deteriorates due to ultraviolet rays and an oxide layer is formed by accumulated contaminants.

- As scratches and scrapes from flying gravel and other debris accumulate on the hard coat, the headlight begins to lose its transparency. Due to the thinness of the hard coat, in some cases the polycarbonate itself may also be damaged. Such damage cannot be repaired by polishing with a polisher or washing. If left as is, the deterioration will continue to progress.

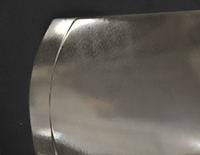

- Yellowing of the hard coat

- The hard coat deteriorates and turns yellow. The countermeasures vary depending on the progress of the deterioration, but in most cases this occurs alongside oxidization due to an accumulation of contaminants. If the deterioration progresses further, chipping will occur.

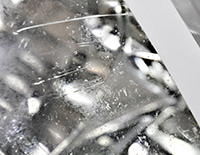

- Cracking of the hard coat

- Cracks open as the deterioration progresses. At this stage, because the hard coat no longer offers protection, the polycarbonate itself begins to deteriorate. This is a phenomenon often seen with non-Japanese vehicles from a certain period. Because polishing with compounds cannot remove the cracks, the hard coat must be removed with waterproof sand paper at this stage.

- Deterioration of polycarbonate

Deterioration of polycarbonate due to deterioration of the hard coat (yellowing, cracks, clouding, etc.)

- Due to the deterioration of the hard coat, the polycarbonate itself is directly exposed to ultraviolet rays. Eventually, it begins to crack. In most cases, the polycarbonate starts to crack before it yellows. Because repairing the cracks is difficult, the part must be replaced.

Headlights: Contents

Related Products