- FE News»

- PPS News»

- Jun. 23, 2025

- Notice of Specification Change for ECHELON Zen-Xero Series Maintenance Bags

- Oct. 31, 2024

- [News Release R-1020] Release of "ECHELON Zen-Xero DYNAMIX”

- May. 15, 2024

- [News Release R-1019] Release of "ECHELON Ver.3.0”

- Oct. 02, 2023

- [News Release R-1018]Compound that achieves a genuine finish Full Renewal of “KATANA” Series

- Jun. 27, 2023

- [News Release] A final finishing compound that achieves a beautiful wet gloss. "KATANA DARK-SHOT" is Released.

Cleaning method

Removal of contaminants from the surface of the headlights

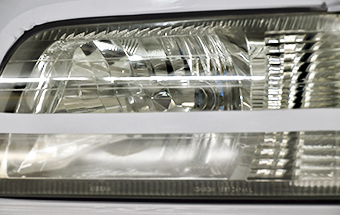

The surfaces of the headlights have yellowed. This is the most common condition in the early stages of deterioration.

Example of polishing with METAL AID

The upper half is a photograph taken after polishing with METAL AID and a wool buffing pad. You can see that the oxidized film has been removed and the transparency has been restored.

However, while the transparency has been restored, the yellowing has not been reversed. This is because cloudiness and yellowing caused by the oxidized layer is entirely separate from yellowing of the hard cover itself. Light oxidation or yellowing can be removed without damaging the hard coat. In addition, by removing the oxide film on the surface, it can be seen that, alongside the yellowing, the hard coat has deteriorated with the orange peel effect.

Polishing of the hard coat

If the problem was corrected in the surface treatment stage described in the previous section, there is no need for additional polishing with sand paper. However, if the hard coat continues to show problems like in the below photograph, it must be removed through polishing. The hard coat is very strong, making it difficult to remove by polishing with a compound. For that reason, waterproof sand paper is normally necessary. Despite the high hardness, unlike clear coat for body paint, hard coat is only 5μ thick. As such, it can be removed without using extremely rough sand paper. Once the hard coat is gone, you will be polishing the polycarbonate directly. Because polycarbonate's hardness is only around HB, using coarse sand paper will scratch the surface more than necessary. Removing those scratches requires a great deal of time and effort. Efficient polishing with minimal scratching can be achieved by using 600 to 800 grit sand paper if there are scratches from flying gravel and other debris, or 1000 to 1200 grit sand paper if there are only light scratches and yellowing. When polishing a headlight lens, just like the vehicle body, it is best to select a polishing method appropriate for the condition of the headlight. Doing so will both shorten the time required and result in a more beautiful finish.

This is the headlight after polishing. It was polished using 800 grit, then 1200 grit, then 1500 grit and lastly a compound.

Headlight cleaners

In recent years, many “simple headlight cleaners” have been sold on the mass market. These products are generally designed to remove contaminants on the surface of the headlight by dissolving them with petroleum-based solvents.

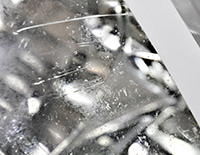

Headlight clouded by an oxide film

Cleaning with a cleaner reduces the cloudiness and removes contaminants from the surface.

You can see the effect the cleaner has on surface contaminants. However, it only removes the contaminants from the surface. It does not clean the hard coat. While these products can be expected to work for slight stains or dullness, they would not be very effective for severe deterioration of the hard coat, and the condition would quickly deteriorate again. In addition, since these products use petroleum solvents, leaving them applied to polycarbonate for long periods of time may cause cracking and cloudiness. Caution is required. These products offer a simple cleaning and nothing more, but consumers could use them for DIY cleaning, while professional detailers could use them for pretreatment prior to a full cleaning, or as a simple option on their service menu.

Headlights: Contents

Related products