- FE News»

- PPS News»

- Jun. 23, 2025

- Notice of Specification Change for ECHELON Zen-Xero Series Maintenance Bags

- Oct. 31, 2024

- [News Release R-1020] Release of "ECHELON Zen-Xero DYNAMIX”

- May. 15, 2024

- [News Release R-1019] Release of "ECHELON Ver.3.0”

- Oct. 02, 2023

- [News Release R-1018]Compound that achieves a genuine finish Full Renewal of “KATANA” Series

- Jun. 27, 2023

- [News Release] A final finishing compound that achieves a beautiful wet gloss. "KATANA DARK-SHOT" is Released.

Verification of restoration methods

In the previous section, we reviewed the causes of corrosion in moldings, but how can that corrosion be reversed? Here, we will examine and test restoration methods from multiple perspectives. In auto detailing work, the traditional options for restoration and cleaning of deteriorated parts are chemical treatment or polishing. We tested and compared a variety of products for each method, including both products on the market and our own original products.

Test 1: Chemical treatment

Unlike aluminum itself, anodized moldings of European cars have excellent corrosion resistance. Nevertheless, even anodized aluminum is limited in its resistance to strong acids and strong alkalis, which will eventually cause it to corrode. For this test, we turned that principle on its head by forcibly inducing reactions in an attempt to remove corrosion.

Sample 1:

Acidic chemical (pH 4.0)

This is an acidic remover intended to remove water spots from painted surfaces and window glass. Since accumulations of spots are one aspect of molding deterioration, we thought that it might be effective.

Acidic chemical (pH 4.0)

This is an acidic remover intended to remove water spots from painted surfaces and window glass. Since accumulations of spots are one aspect of molding deterioration, we thought that it might be effective.

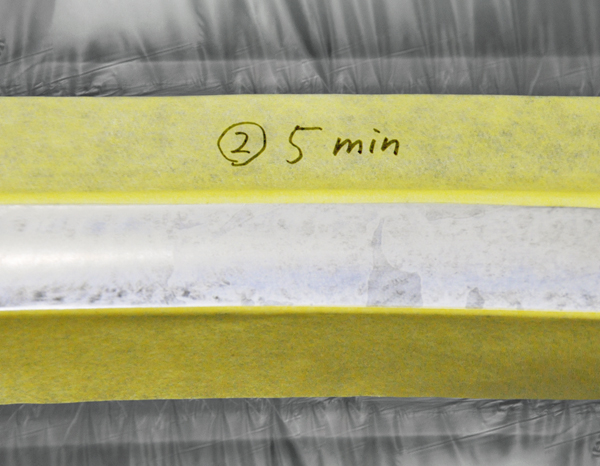

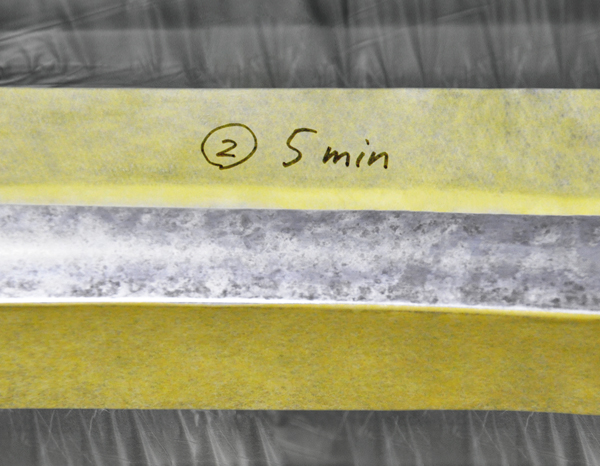

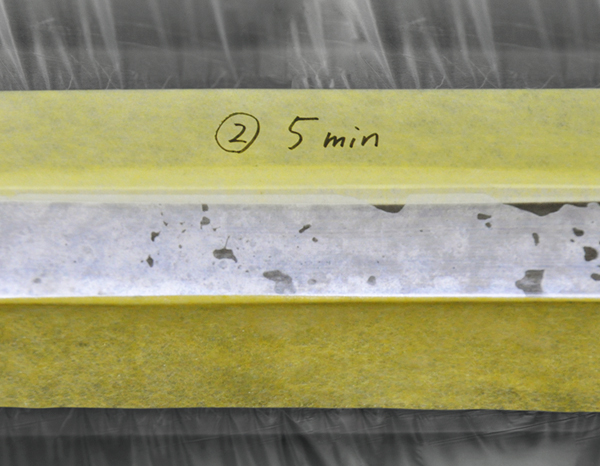

Sample 2:

Alkaline chemical (pH 12.5)

This is a strongly alkaline detergent with the potential to aggressively remove the contaminants and limescale thought to be one cause of cloudiness on moldings. In addition, we will investigate what phenomena occur as properties of anodized aluminum in response to an attack by a strong alkali.

Alkaline chemical (pH 12.5)

This is a strongly alkaline detergent with the potential to aggressively remove the contaminants and limescale thought to be one cause of cloudiness on moldings. In addition, we will investigate what phenomena occur as properties of anodized aluminum in response to an attack by a strong alkali.

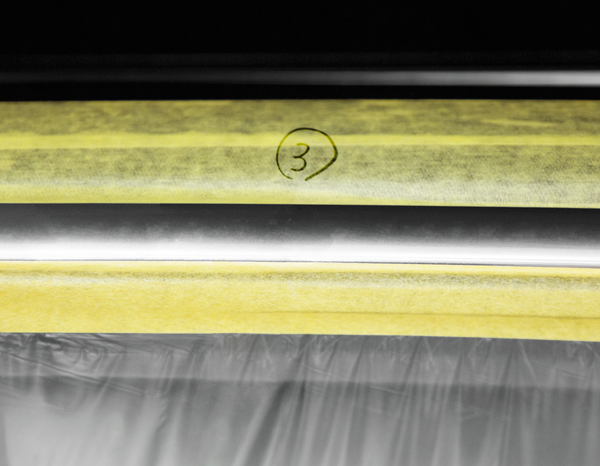

Sample 3:

Sodium hydroxide (alkaline, pH 14.0)

This is a strongly alkaline chemical used to strip the anodic film from aluminum. As such, we thought that applying it to the film may also be effective for removing

Sodium hydroxide (alkaline, pH 14.0)

This is a strongly alkaline chemical used to strip the anodic film from aluminum. As such, we thought that applying it to the film may also be effective for removing

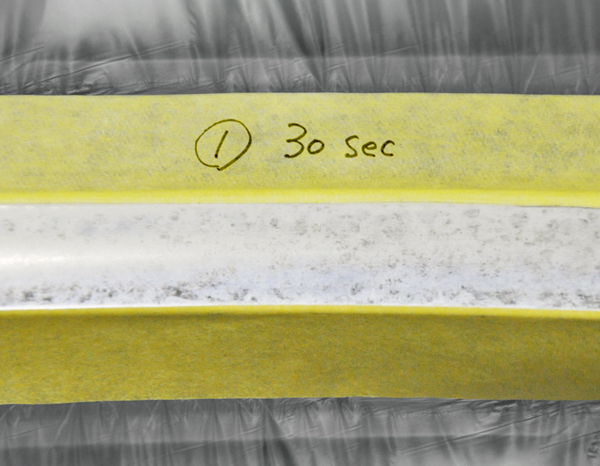

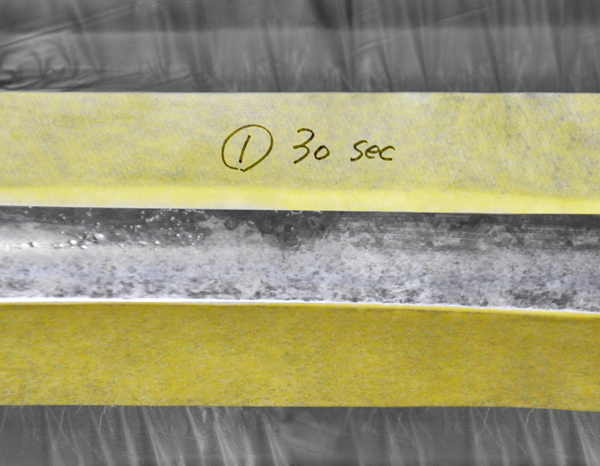

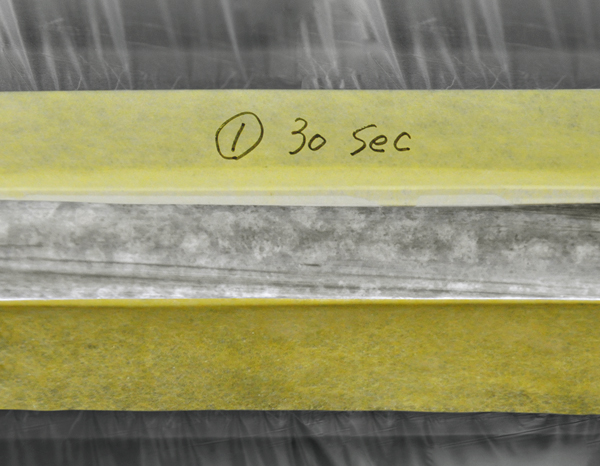

We applied appropriate amounts of each of the above samples to a New Micro Suede cloth, which we rubbed on the surface of the molding for 30 seconds with our fingers. We then observed the changes to the surface. In addition, we soaked pieces of tissue paper in each of the chemicals and left the paper on the surface of the molding for 5 minutes. We then observed the changes to the surface.

■Results after 30 seconds

As can be seen from the above results, using strongly acidic or strongly alkaline chemicals on the surface of anodized molding always produced cloudiness, albeit to varying degrees. However, when using the separately tested SPOTRIMMER (Water Spot Remover), diluted at least 3-fold, a slight reduction of spots was evident in the 30-second wiping test. As such, it may have a positive effect when used in conjunction with polishing. Additionally, for the surface that became severely cloudy as a result of the test, it was not possible to fully repair the damage through polishing afterwards. For that reason, the use of these chemicals on molding requires considerable verification and confirmation.

Test 2: Treatment with abrasives

The standard method for cleaning the various metal parts of a vehicle is to polish them with an abrasive. There are a wide variety of abrasives, from standard ones used for polishing painted surfaces to specialized abrasives designed for particular materials. We investigated what types of abrasive are effective against the deterioration that plagues professional detailers.

Testing conditions

Each product was tested under the following conditions.

Test vehicle: Audi A6 2010

KYOCERA AS555M electric orbital sander with 3M Scotch-Brite T7760 pad

Each product was tested under the following conditions.

Test vehicle: Audi A6 2010

KYOCERA AS555M electric orbital sander with 3M Scotch-Brite T7760 pad

Sample 1:Consumer-oriented abrasive for metal surfaces (imported)

This product belongs to an American consumer brand and is widely used for DIY projects.

After polishing, the cloudiness was largely eliminated, but a few spots remained upon close inspection.

After polishing, the cloudiness was largely eliminated, but a few spots remained upon close inspection.

Sample 2:Abrasive for automobile paint

This is a major product with a particularly wide polishing range, even compared to other abrasives for painted surfaces. Its cutting power ranges from medium cut to finishing level.

After polishing, the cloudiness was reduced, but almost all of the spots remained.

After polishing, the cloudiness was reduced, but almost all of the spots remained.

On the basis of the above results, METAL AID can be recommended for the restoration of deteriorated molding. METAL AID was developed specifically for the polishing of deteriorated molding. METAL AID goes beyond simple polishing by incorporating chemical action for greater efficiency. Also, as mentioned in the first test, using SPOTRIMMER (Water Spot Remover), diluted at least 3-fold, to clean the polished parts before polishing with METAL AID reduced the time required to obtain the same effect. As such, the use of SPOTRIMMER appears to be effective as part of the process for polishing molding.