- FE News»

- PPS News»

- Jun. 23, 2025

- Notice of Specification Change for ECHELON Zen-Xero Series Maintenance Bags

- Oct. 31, 2024

- [News Release R-1020] Release of "ECHELON Zen-Xero DYNAMIX”

- May. 15, 2024

- [News Release R-1019] Release of "ECHELON Ver.3.0”

- Oct. 02, 2023

- [News Release R-1018]Compound that achieves a genuine finish Full Renewal of “KATANA” Series

- Jun. 27, 2023

- [News Release] A final finishing compound that achieves a beautiful wet gloss. "KATANA DARK-SHOT" is Released.

Molding material and surface treatment

As mentioned above, deterioration and corrosion of window molding is common on European cars, but rarely seen on Japanese cars. Differences in the materials used for molding play a large part in this. European cars tend to use aluminum for window moldings, while Japanese cars use stainless steel, even for otherwise identical moldings. Why are different materials used for the same part? European manufacturers must have some reason for preferring aluminum, despite stainless steel's reputation for strength and resistance to corrosion. While we cannot decisively state a clear reason, environmental concerns are relevant. European environmental regulations are stricter than most of the world, including with regard to automotive recycling. As such, it appears that aluminum is used because of its excellent recyclability. Of course, there are likely various other reasons, such as cost and ease of use. Let's compare the differences between aluminum and stainless steel.

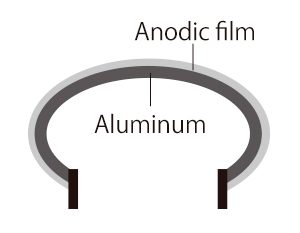

Aluminum molding (mainly used in European cars)

Aluminum is used in various parts of automobiles due to its lightness and suitability for processing. Because aluminum is an amphoteric metal that oxidizes in response to both acids and alkalis, it naturally lacks durability. In order to suppress the reactions that cause oxidization of the surface and provide durability, the aluminum is anodized.

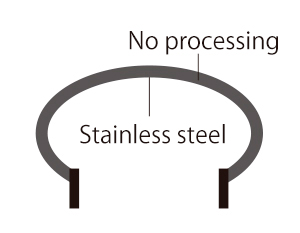

Stainless steel moldings (mainly used in Japanese cars)

Stainless steel is a steel alloy that contains chromium and nickel to prevent rusting. The chromium bonds with oxygen in the air to form a passive film on the surface, providing weather resistance that makes stainless steel suitable for use outdoors, even without plating or coating. In terms of cost, suitability for processing and recyclability, however, aluminum has the advantage