- FE News»

- PPS News»

- Jun. 23, 2025

- Notice of Specification Change for ECHELON Zen-Xero Series Maintenance Bags

- Oct. 31, 2024

- [News Release R-1020] Release of "ECHELON Zen-Xero DYNAMIX”

- May. 15, 2024

- [News Release R-1019] Release of "ECHELON Ver.3.0”

- Oct. 02, 2023

- [News Release R-1018]Compound that achieves a genuine finish Full Renewal of “KATANA” Series

- Jun. 27, 2023

- [News Release] A final finishing compound that achieves a beautiful wet gloss. "KATANA DARK-SHOT" is Released.

Headlight Protection System - Special headlight film

More flexible, more beautiful:

Headlight Protection Film

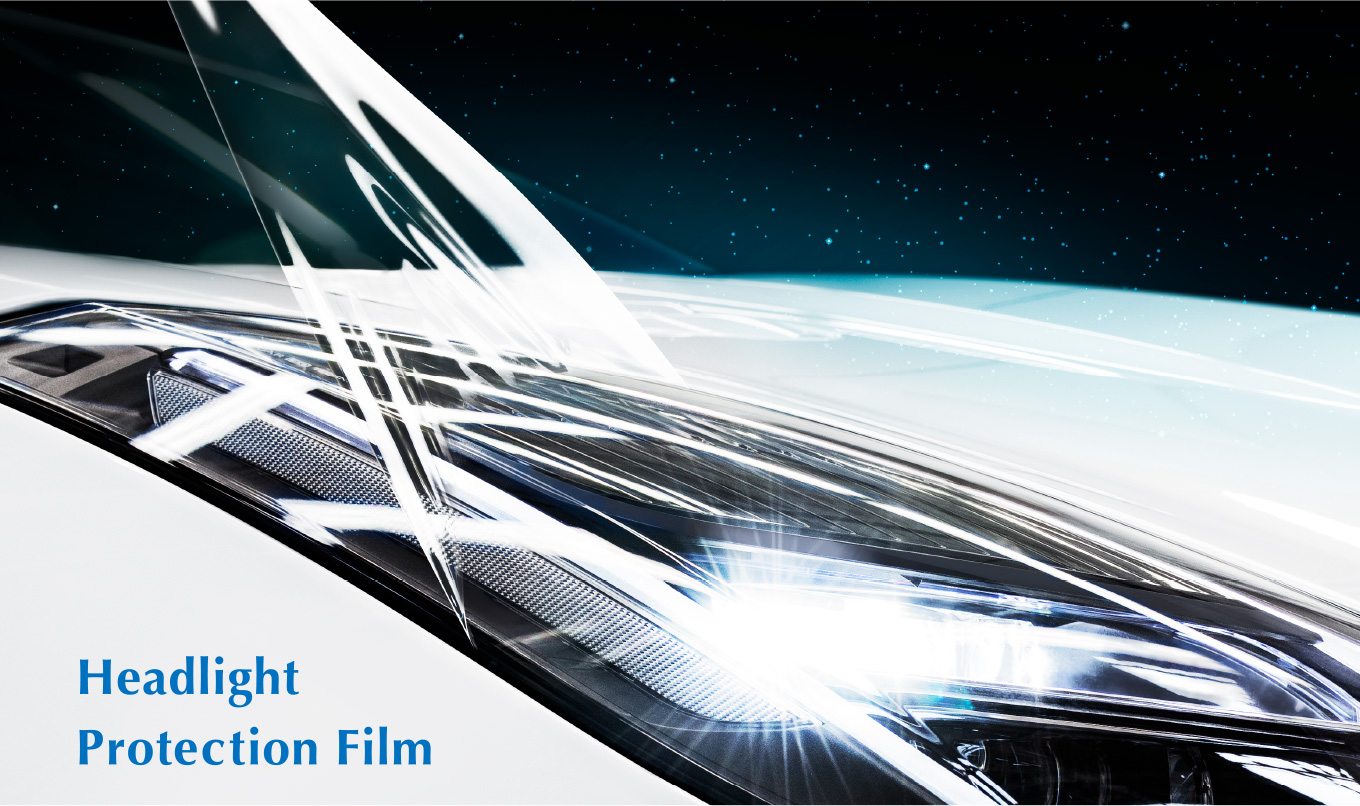

It achieves a high level of color reproduction and reproduces the true transparency and color temperature of headlights.

With its improved ability to follow curves, it can now be applied easily to parts with sharp radii, where before it took a long time to set.

The special material has been adjusted to further improve transparency, offering a more beautiful, sharper brilliance than ever.

Headlight Protection Film to prevent yellowing, scratches and stains

Prevents yellowing and clouding of headlights for five years

Headlight Protection Film protects headlights from yellowing and deterioration.

Its effects are striking, and tests by public research institutions have shown the following.

●Verification test with a Sunshine Weather Meter

A Sunshine Weather Meter is a special machine that simulates the everyday environment. Using this machine, a headlight was irradiated for a period equivalent to five years of normal exposure, with one part covered in film and the other part not covered. As you can see, the part of the headlight covered in film remained transparent, while the other part yellowed intensely.

Accelerated weather resistance test * Sunshine Weather Meter Xe-WOM 3000 hour test (equivalent to five years of real-world exposure)

- Covered part

- Uncovered part

- Covered part

- Uncovered part

●UV blocking rate

Ultraviolet rays are the most significant cause of yellowing in headlights. Polycarbonate and the protective hard coat applied to it change composition when exposed to ultraviolet rays, which leads to yellowing and cloudiness. Headlight Protection Film prevents that by blocking over 90% of ultraviolet rays. When the UV transmittance was measured in accordance with JIS standards to determine what percentage of UV radiation is being blocked, the results were astonishing:

UV blocking rate 93.6%

* Test conducted in accordance with the methods specified in JIS S3107 (film for vehicle windows)

In other words, very few ultraviolet rays pass through.

Prevents damage from flying gravel and scratches

The film used for headlight protection is scratch resistant and made from high-quality polyurethane, with a thickness of 150 microns. That durability was demonstrated in a test using specialized equipment to simulate driving speeds of 200 km. The test found that damage from flying gravel was absorbed by the film without leaving any scratches on the underlying panel.

●Physical resistance test using a gravel meter to simulate driving speeds of 200 km/h

A test piece, half covered in film, was inserted into the gravel meter. Pebbles were also inserted to fly and cause damage.

You can see that the test piece is covered with countless marks from the pebbles.

Removing the film reveals that there is no damage at all on that side.

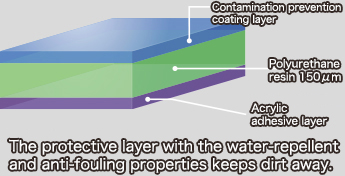

Prevents everyday accumulation of contaminants

Headlight Protection Film consists of a non-yellowing, high transparency thermoplastic polyurethane base beneath a fluorine-treated coating layer that prevents contamination. The film also uses an acrylic adhesive selected for its suitability for the polycarbonate material of the headlight and the hard coat.

●Structure of Headlight Protection Film

- Contamination prevention coating layer A hard layer containing fluorine manufactured through a special process, providing thorough protection from contaminants and excellent water repellency

- Polyurethane resin 150μm A highly transparent, 150-micron thick layer of polyurethane resin designed for elasticity and resistance to yellowing, providing protection from physical damage

- Acrylic adhesive layer Adhesive selected for its suitability for the polycarbonate material of the headlight and the hard coat

Maintains light intensity that meets inspection standards

Headlight Protection Film is a colorless and highly transparent non-yellowing polyurethane film.

Our company conducts light intensity tests in accordance with vehicle inspection safety standards. Headlights with Headlight Protection Film pass these inspections without issue.

●Initial verification with actual vehicles

We applied the film to an actual vehicle and measured the light intensity of the headlight under the same conditions used for vehicle inspections.

| Before installation | 19,400 candela |

|---|---|

| Immediately after installation | 21,200 candela |

| One month after installation | 22,600 candela |

As you can see, installing the film did not decrease the light intensity. Furthermore, the intensity

increased as the film settled and became more stable one month later.

We will continue to take measurements and update the information on our website.

●Honda Insight: Results of installation on a 3-month old car over time

| Time since installation | Low beam | ||

|---|---|---|---|

| Regulatory standard: 64+ | |||

| Left | Right | ||

| Before installation | 116 | 159 | |

| Measurement #1 | Immediately after | 115 | 159 |

| Measurement #2 | One year after | 101 | 132 |

| Measurement #3 | Two year after | 93 | 111 |

| After removal | 102 | 130 | |