- FE News»

- PPS News»

- May. 15, 2024

- [News Release R-1019] Release of "ECHELON Ver.3.0”

- Oct. 02, 2023

- [News Release R-1018]Compound that achieves a genuine finish Full Renewal of “KATANA” Series

- Jun. 27, 2023

- [News Release] A final finishing compound that achieves a beautiful wet gloss. "KATANA DARK-SHOT" is Released.

- May. 22, 2023

- [News Release] Full renewal of buffing pad category Brand integrated into HAYABUSA

- Apr. 12, 2023

- Announcement of Office Relocation

What it UNIGLOBE AUTO FILM?

»Back to UNIGLOBE AUTO FILM top

Professional technique can bring out these films’ top-class color tone and functionality. From sophisticated smoky film to insulating film which keeps you comfortable, we offer a diverse lineup of products.

-

Excellent insulation

New to the lineup this season is the CLARIO series, a high-performance insulating film which has inherited the same color as the longtime popular USG series.

-

UV reduction

All of our films reduce harmful UV radiation by more than 99%.

-

Shatterproof effect

In case any glass breaks in an accident, a film can prevent shards of glass from flying around, thereby keeping you safe inside the vehicle.

-

Protection of privacy

Films can protect your privacy from prying eyes outside the vehicle while offering amazingly clear visibility from inside the vehicle.

-

Sophistication

You can choose from a wide variety of colors. The Z-type has a unique shine which offers a high-class feel.

Other types, such as mirror and clear types, offer an even wider selection of styles.

Product LINEUP

-

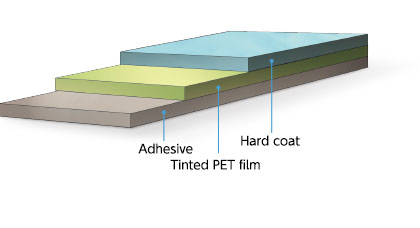

CLARIO Series

This heat-absorbing insulating film is made by impregnating a hard coat with a high-performance ITO.

-

CR Type

Although basic, it has unrivaled functionality. The latest technology has been condensed into this 25 micron film.

-

Z Type

The spattering method has been used to form multiple layers of special metals. This top-class film has high visible light transmittance and insulation, as well as being very fashionable.

-

R Type

The highly transparent UV-reducing type is shatterproof, while the Glasweld Mirror type is highly fashionable.

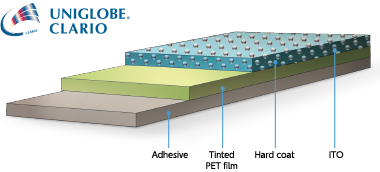

UNIGLOBE®AUTO FILM uses the solution dyeing technique (mass-dyeing)

The UNIGLOBE AUTO FILM CR-type uses the SOLUTION DYEING technique. Unlike traditional methods, this technique adds color at the resin stage, before the PET film is molded. This technique can achieve an extremely even color and provides excellent transparency and durability. Furthermore, because of the uniform coloring, no unevenness arises during thermoforming, making the overall process very easy to use. However, quality can vary with the solution dyeing or spin dyeing techniques. Some products prioritize cost and use low quality ingredients, using additional ingredients to make adjustments during the manufacturing process. Such products look cloudy and warping can be seen in the PET film. UNIGLOBE AUTO FILM distinguishes itself from such products. Your critical professional eye will see the difference.

CLARIO colored series

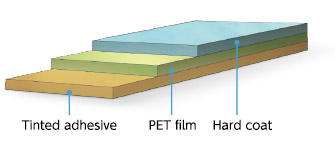

The CLARIO colored series adds high-performance insulating capabilities to the existing USG standard products. The USG series’ hard coat layer is impregnated with an ITO with a high IR absorbency, which offers excellent heat-blocking without the conventional film shade.

Dyeing methods of other films

What dyeing methods are used for automotive films other than SOLUTION DYEING?

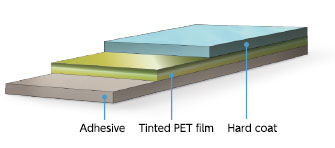

Dyed film

This type of dyeing uses solvents or water to dye the PET film. Although it is highly transparent, it is difficult to evenly color the PET’s inner layers, causing it to fade and reducing its durability. It shrinks very well during thermoforming, but due to its sensitivity to heat, the thermoformed section may sometimes be uneven.

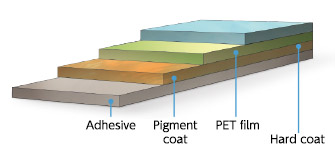

Pigment coating film

This dyeing method applies a coating of pigment to a clear PET film. The pigment’s resistance to fading makes the film durable. However, because the pigment consists of large particles, the film causes light to diffuse and become cloudy, offering inferior transparency. Overall, these films feel hard and tend to take a long time to form.

Colored adhesive

products and in the tropical regions of Southeast Asia and Central America or countries with low costs of living. Due to their inferior coloring and durability compared to other manufacturing methods, however, they are not often used as professional products. Nevertheless, in recent years such films have at times been distributed as low-cost professional films. Although they have low prices, these products also have low durability and quality, and there have been cases of adhesives dissolving simply by adding an application fluid. If used as a professional film, there is a chance that customers will lodge complaints, and therefore we cannot recommend this type of product.