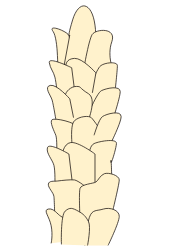

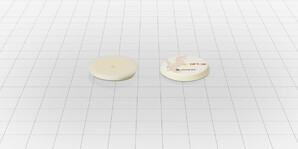

The characteristics of wool vary greatly depending on the breed, age, and place of production of the sheep. The synonymous merino is the most widely distributed wool in the world and is classified as one of the finest wools. Furthermore, varieties are divided according to the country of origin, and among them, Australian Merino is the most popular and high quality.

Australian Merino Wool

It is characterized by being the whitest, thinnest and most crimped wool. The fibers are long, strong, and flexible, making it the most suitable wool for clothing. It is classified into three types according to the thickness of the fiber.

-

1

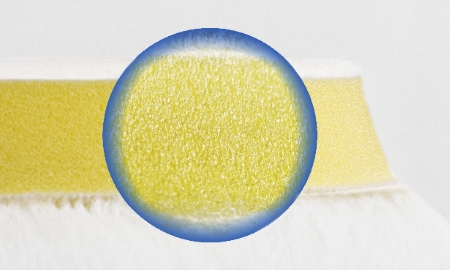

1Fine Merino Wool

It is used for high-grade fine worsted fabrics.

- Fiber thickness

- 18-19 microns

- Average fiber length

- about 70-75mm

-

2

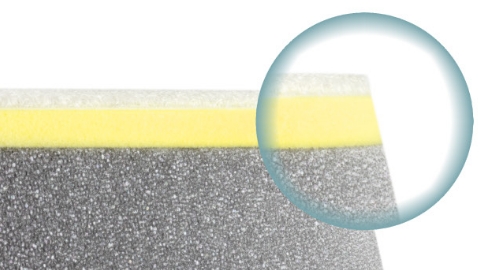

2Middle Merino Wool

It is used for worsted fabrics and ultra-luxury blankets.

- Fiber thickness

- 20-22 microns

- Average fiber length

- about 90 mm

-

3

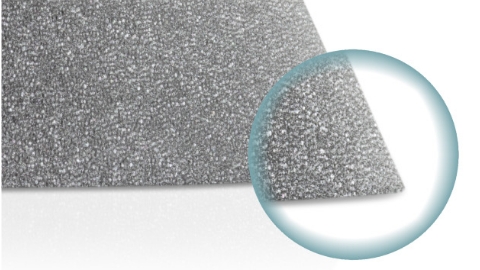

3Strong Merino Wool

It is used for worsted fabrics and luxury blankets.

- Fiber thickness

- 23-25 microns

- Average fiber length

- about 100 mm