- FE News»

- PPS News»

- Jun. 23, 2025

- Notice of Specification Change for ECHELON Zen-Xero Series Maintenance Bags

- Oct. 31, 2024

- [News Release R-1020] Release of "ECHELON Zen-Xero DYNAMIX”

- May. 15, 2024

- [News Release R-1019] Release of "ECHELON Ver.3.0”

- Oct. 02, 2023

- [News Release R-1018]Compound that achieves a genuine finish Full Renewal of “KATANA” Series

- Jun. 27, 2023

- [News Release] A final finishing compound that achieves a beautiful wet gloss. "KATANA DARK-SHOT" is Released.

Architectural window film / Optical properties to consider

Architectural window film / Optical properties to consider

Each type of film has different optical properties. By comparing these values, you can get an idea of what sort of characteristics the film possesses. For this reason, they are important selection criteria. In this section, we will explain the key optical properties to consider when selecting architectural film.

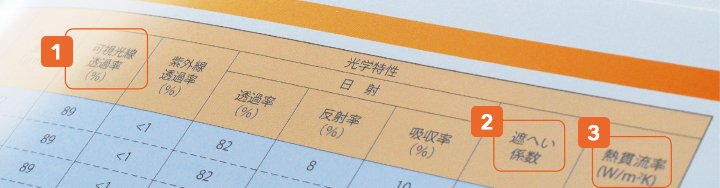

1 Visible light transmittance

This is an indicator of the brightness of sunlight entering a room. 50% or above indicates that there is no sense of darkening, while 70% or above indicates that the presence of the film is almost unnoticeable. UNIGLOBE R&C products use materials with 70% or higher visible light transmittance to achieve both functionality and brightness.

2 Shading coefficient

This is an indicator of the effect of solar heat blocking. It indicates the ratio of solar radiation that enters a room when film is installed on the glass, with a value of 1 being equivalent to the amount of solar radiation that enters the room through a clear 3mm sheet of glass. The lower the value, the greater the heat shielding effect, which helps reduce the load on cooling systems. Typically, values of 0.85 or below are considered to represent a certain effect. Additionally, the method of measuring and calculating this value is defined by the Japan Industrial Standards (JIS), and the values listed in each manufacturer's catalog are based on this standard. However, please be aware that some manufacturers may use figures based on their own standards or non-Japanese standards.

3 Thermal transmittance

This is an indicator of the heat blocking performance when film is installed on the glass. When the temperature on one side of a structure like a wall or window differs from the other side, heat will pass through that structure from the warmer sider to the cooler side. The "U-value" refers to the amount of heat that passes through one square meter of glass per hour, expressed in watts, when there is a temperature difference of 1°C (or 1K) between the inside and outside. The smaller the U-value, the better the heat blocking effect. The units are expressed as W/(m2・K), which is read "watts per square meter Kelvin."

Relationship between shading coefficient and visible light transmittance

In general, films with a low shading coefficient also have low visible light transmittance. Reflective films (shading coefficient between 0.25–0.50) which use metals with excellent infrared ray blocking are still widely used, but these films also block a substantial portion of visible light (visible light transmittance of 15%–45%). This has the drawbacks of dimming the room and darkening the view from the window. Types that use dyed film can reduce the visible light transmittance (5–30%), but because they do not block infrared rays, the shading coefficient cannot be lowered beyond the expected level. Recently, films that block substantial amounts of infrared light without blocking visible light have been attracting attention. This type makes it possible to reduce heat without losing the glass's original sense of openness.

Types of glass Mainly used for buildings

Depending on the type of glass, installation may be difficult. Please refer to the below overview of glass types.

Float glass

Float glass is a type of sheet glass made through a particular manufacturing process. It has excellent smoothness, light transmission and transparency, and distorts neither images seen through the glass nor reflected images. There are many types of this glass with different dimensions, thicknesses, etc., and it is used for a wide variety of purposes, such as windows of buildings, display windows and showcases.

Plain sheet glass

This refers to glass made mainly of calcium silicate, sodium silicate and silicon dioxide. Its features include glossiness and excellent workability. Plain sheet glass predates other types and is used for window glass in conventional homes.

Patterned glass

Patterned glass has an uneven surface (embossed pattern) on one side. It provides lighting while obstructing the view, making it popular for locations that require privacy. It is highly effective for general architecture, furniture, interior design and decoration.

Wired or mesh glass

This type of glass has a wire mesh embedded within the glass. The mesh stops shards from falling out of the frame, even if it cracks during a fire. This helps to prevent the spread of fires. It is used especially for openings, skylights and other places where there is a risk that fire may spread.

* The thickness is fixed.

⇒ 6.8mm or 10mm

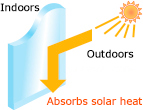

Heat-absorbing plate glass

This type of glass is tinted by adding a miniscule amount of metal to the composition of the glass. It also absorbs solar heat, reducing the amount that passes through the glass. This glass is used for the windows of automobiles, railway cars and buildings of all kinds, taking advantage of its beautiful coloring and excellent performance.

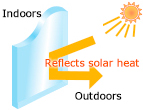

Heat-reflecting plate glass

This type of glass has metal oxides baked onto the surface that reflect solar energy, reducing the load on the cooling system and saving energy. The exterior side has a mirror-like appearance, reflecting the sky and surrounding scenery. The effect is beautiful and has made this glass popular for the exteriors of everything from ordinary buildings to skyscrapers.

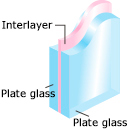

Laminated glass

This high-safety glass consists of two pieces of glass bonded together using a strong resin film. The strength of the resin film provides strong impact resistance and prevents glass shards from scattering if the glass breaks. It is used in locations where safety is required, such as automobile windshields, skyscraper windows and entrances to buildings where many people gather.

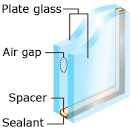

Double glazing

This type of glass enhances heat insulation by enclosing dry air between two sheets of glass. Because it helps save energy and prevents condensation, this glass is used in ordinary homes, railway cars, refrigerated showcases, etc. For typical residences, a 6.8mm wired pane for the exterior and a 3mm float glass pane for the interior (with a 6mm air gap) is standard.

Tempered glass

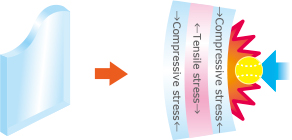

Tempered glass is made by heating a sheet of glass just below the softening point (approximately 700°C), followed by rapid cooling with air currents to form a compressive stress layer on the surface. With three to five times the strength of float glass of the same thickness, this type of glass has superb durability. In the unlikely event that it does break, the entire surface will crumble into granular chunks, preventing serious injuries from the pieces. It can also withstand sudden temperature changes very well. Because of its ability to prevent serious injuries, this glass is used for windows of automobiles, railway cars, ships and aircrafts, as well as doors of schools and other buildings.

Product lineup

UNIGLOBE Residential & Commercial is a comprehensive brand of architectural window films, a new category in UNIGLOBE's lineup. In cooperation with SKC, one of the world's leading polyurethane manufacturers, we offer a range of sophisticated and high-quality products to meet your needs.

WINCOS Architectural Window Film

This architectural window film is from Lintec, a leader in the Japanese market for automotive film. You can select from a wide lineup of films to suit your application and purpose.